Previous guillotines models, such as the Schmidt guillotine model, were quite basic devices that, among other things, suffered from a problem that was never solved: The impact of the mouton or driver against the base of the risers.

The mouton slid along the risers, and the simply impact against the end of the grooves ended up breaking or damaging some parts of the machine, no matter how much the executioners tryed to cushion the collision by adding cloths or leather into the grooves.

Apart from this problem, the upper half of the lunette or half-moon in these previous guillotines was hand-operated, meaning the executioner had to hold the upper half while his assistants pushed the prisoner forward until the head was inside the hole. Besides, the expansion of the wood in rainy seasons or excessive humidity conditions could also produce more than one problem, blocking some parts and consequently delaying the whole execution process.

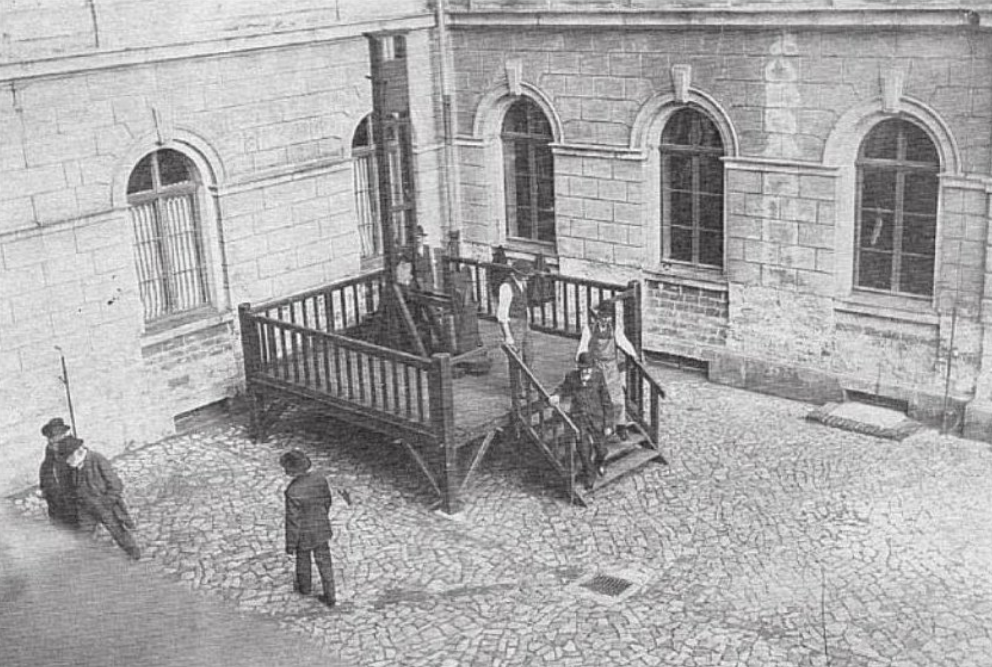

Schmidt guillotine was not easy to assemble and disassemble, taking quite a long time to leave it fully operational, and considering that once the Revolution was over it was no longer necessary to leave the machines permanently installed on their respective gallows, being only necessary to be instaled when someone sentenced to death by ordinary justice had to be executed. This problem and the fact that at that time in the French judicial system the prisioner was not informed of the date of its execution just until an hour before it, made necessary to have a machine that could be assembled and disassembled really quickly. In fact, it was quite normal to see guillotines ready to be used in the very door of the prison until November 1870, from that date on, the executions on gallows in public squares were abolished, among other things because they became parties where people from all over France came to enjoy that bloody event.

The metropolitan territory was divided into four zones, each one with its own executioner and three assistants. When any sentence had to be carried out, the disassembled machine was transferred to the city where the prisoner needed to be executed. The guillotine was assembled during the early morning of the execution day, while a large contingent of gendarmes was in charge of keeping the curious away.

When the fatal time for the prisoner finally arrived, he was taken out from prison by some gendarmes and in just a matter of less than two minutes the execution process was over, the body transferred to the morgue and the guillotine quickly disassembled and returned to Paris or the judicial district of origin.

For all these reasons, it was clearly necessary to have a much more easily removable, safer to handle and more robust guillotine that did not require the smooth and leveled surface of a gallows for its installation. And precisely the guillotine model created in 1868 by Alphonse-Léon Berger satisfied these requirements. Monsieur Berger had been working as an executioner in Corsica since 1863, combining this activity with some other works as a carpenter.

Berger was born in Perpignan on February 15, 1841, son of Pierre-Martin Berger, Perpignan executioner. In 1867 he married Virginie Desmorest, daughter of the executioner of Carpentras. When Virginie died in 1875 he remarried Olympe-Marie Roch, the daughter of another executioner, in this case Nicolas Roch.

All this just shows that at that time in France there were authentic dynasties of executioners, families whose members “inherited” the status as an executioner generation after generation.

Berger, who was related to Roch, expected to become the number 1 executioner in France, because his father-in-law, had served as Jean-François Heidenreich’s assistant until his death in 1871, who was designated “Monsieur de Paris “, the chief executioner of the metropolitan France. That´s why, Roch was designated as his successor.

When Roch was finally appointed new chief executioner, two new assistants were assigned to him: Alphonse Berger and Louis Deibler, whose father Josef Deibler, came from a large executioners family too. As you may guess, Berger and Deibler had a tough dispute to become Roch´s successor, who at that time was already 63 years old. Berger assumed that being his son-in-law, the position as a chief executioner was his. However, Roch suffered a sudden death in December 1878 and Louis Deibler named as chief executioner, taking Berger by completely surprise who had to make do with being just his first assistant.

Relations between both of them went from bad to worse. Deibler avoided calling Berger for any execution during the next 20 years, calling instead his son Anatole so he could start learning the profession.

Berger died on June 6, 1906, when he was 65. Deibler carried on being the executioner’s chief and after him his son, the famous Anatole, took his legacy and Berger was left with the only the glory of having created the guillotine that remained until the death penalty abolition in France.

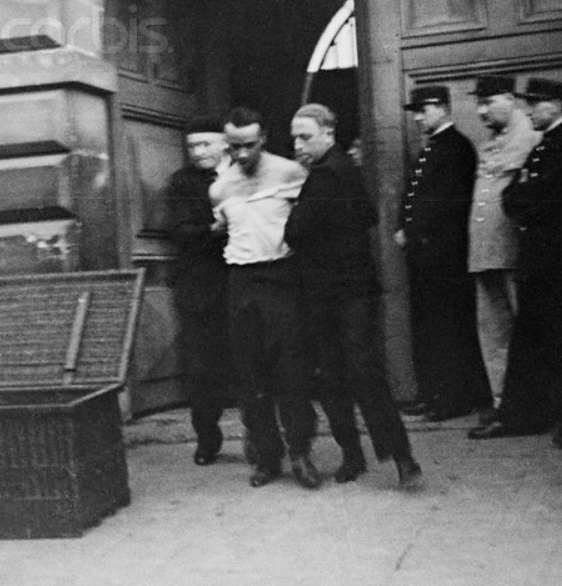

being led into the courtyard of Saint Pierre Prison in Versailles to his execution on the guillotine.

Coming back to the execution process, and after receiving spiritual aid if that was his wish, the prisoner was cut off the collar of his white shirt until his shoulders were visible. A drink of rum and a cigarette was offered to him, and afterwards he was escorted by two guards, the prison director, a representative of the court, the prosecutor’s office and the defense attorney, etc. A few meters from the gate of the prison the executioner, his main assistant and two secondary assistants were already waiting for him.

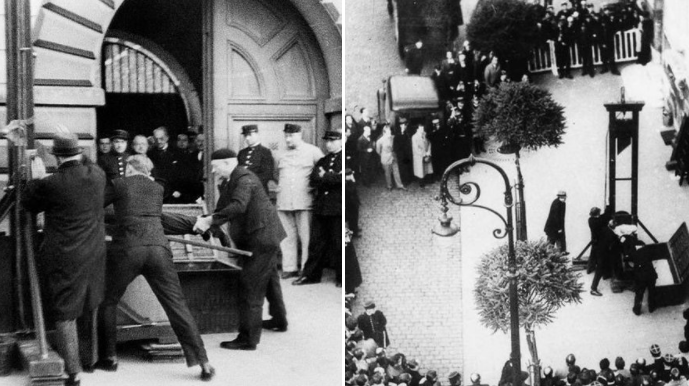

By the time the prisoner came out of the prison the guillotine was ready with the half-moon open. In just a matter of second, and taking the advantage of the shock produced by the sight of the guillotine, the criminal was quickly carried and positioned horizontally by the executioner’s assistants who. When the head was placed in the right position, the main assistant grabbed it by the hair or, if it did not have it or had it very short, by the ears. After that, the executioner pressed the button that released the upper half-moon and practically at the same time, the lever of the mechanism that retained the blade was activated, leaving the blade fall at a speed of around 4 meters per second.

Once the head was beheaded, the body was pushed into the drawer placed at the right side of the guillotine. This drawer was made of wick and covered from the inside with zinc. In the bottom of the drawer a layer of sawdust to soak up the blood.

In short, the time passed from the prisoner’s exit until the blade cut his neck and ended up in the drawer lasted less than 30 seconds. After that the guillotine was disassembled or , in case of a multiple execution, cleaned to leave it ready for the next one.

This executions were always photographed by journalists that came to these events until the government prohibited to take more photos. Despite this prohibition, people kept taking photos of the executions and many times people were payed by journalists to take these photos from their houses until the government decided to finish the public executions in 1939. This final decision was triggered by the execution of Eugen Weidmann in that same year. On the following picture it seems like just a few dozen people witnessed the execution, but beyond the frame there were more than 30,000 people who, since the night before, crowded the area to see how that criminal was executed. When the guillotine was removed, there were even people who rushed to soak handkerchiefs in the blood that was left on the floor.

From that time on, the executions were ordered to be carried out inside the prisons and fully covered with black cloths in order to prevent any picture from the nearby buildings. The secrecy reached the point that no one, except certain officials, knew the place where the guillotine was.

How did the Berger guillotine work?

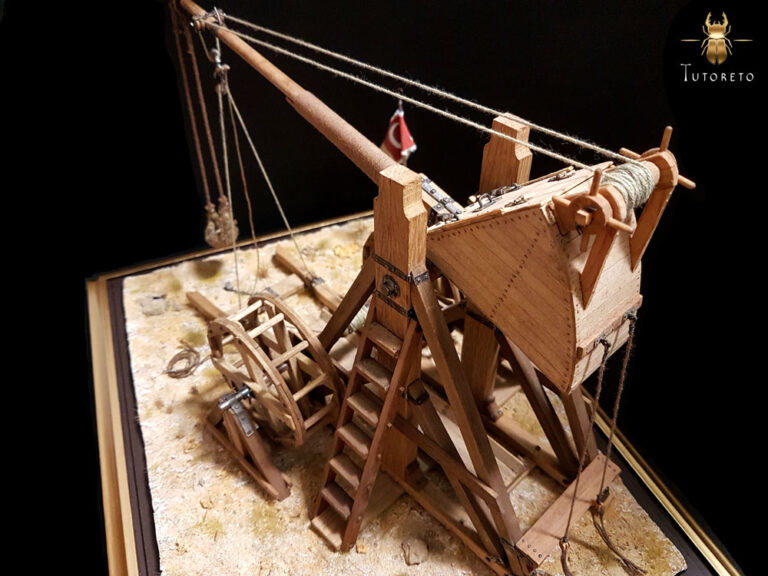

After this long introduction along the development of capital punishment in France, let’s start now explaining some of the most curious details of the Berger guillotine, helping me sometimes with some pictures taken from my personal Berger guillotine model.

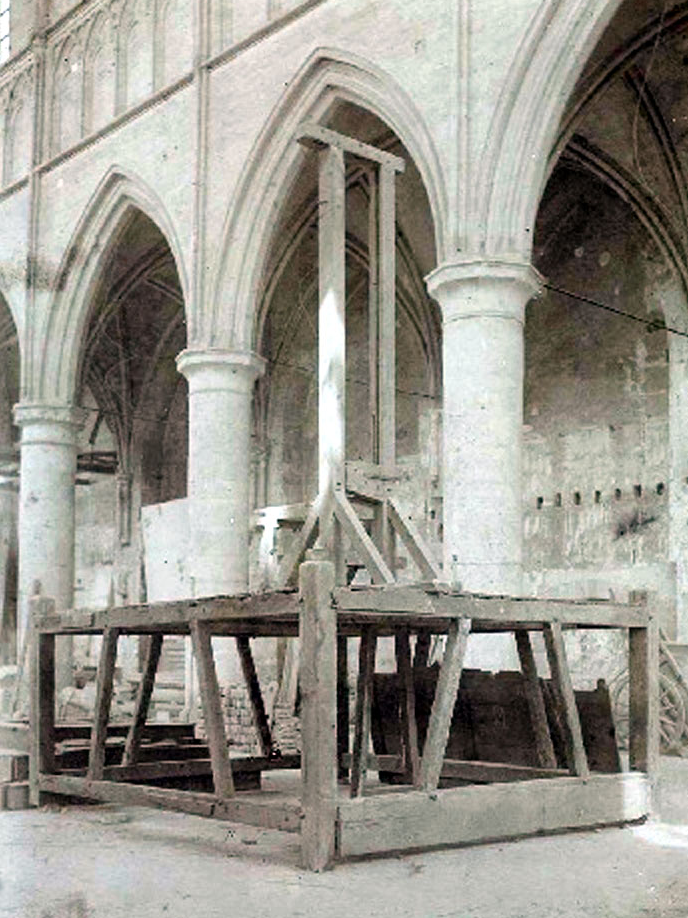

The Berger guillotine was a very well-designed machine, in which construction several materials were used, such as oak wood, bronze or/and steel for those areas more liable to suffer damages or wear. It was created to be easily assembled and disassembled in less than three hours. For that purpose, all the elements were joined using assembly screws, screws that rather than being screwed directly to the wood, some threaded bushings were installed so as the screws could be screwed into them and not get loose eventually.

In this guillotine model a central crossbar was added to the base to improve its stability, because as mentioned before, the gallows disappeared, and consequently, it was necessary to ensure a good leveling of the whole guillotine.

Once the base was perfectly horizontal, the risers where installed using T-shaped iron profiles.

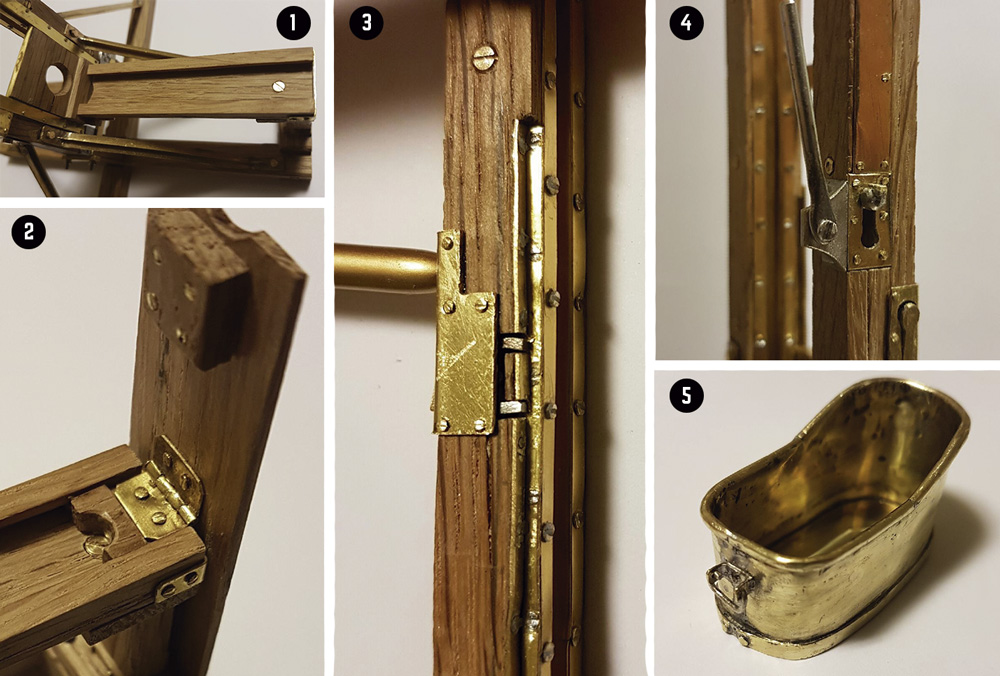

The prisoner was lay down on a table o seesaw moved along a slide attached by a hinge (Pictures 1 and 2 above).

Regarding mechanisms, on the picture 4 you can see the lever that released the blade by pulling it downwards, and on picture 3 the button that that kept the upper half-moon raised.

Picture 5 shows the zinc bucket that replaced the traditional wicker basket. This bucket was more … “hygienic” than traditional wicker as it could be thoroughly washed after use. In fact it was pretty common to place a couple of buckets next to the machine so as they could clean the scene, especially when multiple executions were carried out.

In order to prevent the assistant who held the prisoner’s head from being sprinkled by blood, the screen was placed, which was foldable to facilitate its transport.

But the real complexity of this guillotine was in the mechanism of the capital, whose aim was to hold the blade. As I said, this mechanism was placed inside the upper capital and covered with a sheet metal cover. On that same capital we see the pulley whose rope was also introduced in the capital to hook the blade, which was provided with a pin that automatically fitted into the claw. To open the claw and let the blade fall, there was a thin bar that descended embedded in a groove throughout one of the two risers up to the lever that, by turning it downwards, the claw was opened and the heavy mouton with the blade released. This groove was covered by a long bronze plate screwed to the riser.

The mouton was entirely made of metal, formed by a central frame where the bronze rollers were housed that replaced the fragile tongues of the Schmidt model. A thick sheet metal with a cut-off for the blade was screwed to one side, which was fixed with three through screws. In the upper part of the mouton there was the spike that allowed to block to the claw, as well as the hook for the rope. The total weight of the mouton was between 40-50 kilos. Finally, in the lower part of the mouton there were two protrusions that worked as stops when the mouton fell, that crashed against the coil springs. These springs were fitted into two channels all along the risers that were covered with bronze metal sheets to avoid the wear.

The half-moon was covered by metal in one side and slipped through two bronze blades.

At one side of the seesaw there was panel, where the body of the prisoner fell into the basket. This side panel was fixed to the seesaw by some hinges joined by a long and thin bar that acted as a pin. This tin was bent in an L shape to facilitate its removal when disassembling the guillotine.

Picture below you can see as a summary personal Berger guillotine model fully disassembled.

Source:

For spanish readers I strongly recommend visiting the following link for further information about this guillotine and other interesting topics.

CASTRA IN LUSITANIA: LA GUILLOTINA BERGER (amodelcastillo.blogspot.com)

Pingback: The Berger guillotine | How I made this guillotine model